Internet takes custom tailoring to a wider market

Editor's Note: In this ongoing series on the birth and growth of privately owned Chinese companies that are redefining innovation, China Daily profiles Red Collar, a Qingdao-based Chinese leading menswear manufacturer that is integrating cloud computing technology, big data and the internet of things into clothes manufacturing.

Mass production and personal customization seems to be two contradictory terms. But Chinese leading menswear manufacturer Red Collar has just combined the two by integrating cloud computing technology, big data and the internet of things into clothes manufacturing.

The Qingdao-based company has developed a personal customization platform called "Customer to Manufactory", also known as C2M.

"The platform enables customers to communicate with the manufacturer directly through a mobile application without the involvement of agencies and middlemen," Zhang Daili, founder and chairman of Red Collar, said.

Zhang said C2M involves the whole manufacturing process, including order arrangement, tailoring, clothes material selection, lining and pattern making, with all procedures driven by big data and controlled by computers.

Boosted by the business model, Red Collar's revenues doubled last year to reach more than 3 billion yuan ($452 million), with 70 percent of its orders coming from European and US markets.

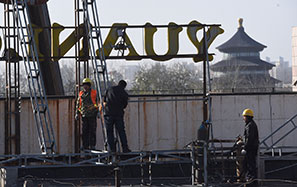

On an assembly line in Red Collar's headquarter factory in Jimo, a county-level city in Qingdao, rows of men suits are hung.

Garments in different colors, styles and fabrics are stored in an orderly fashion with electrical cards that contain information about customer requirements.

When workers scan an "ID card" through a special terminal in front of their working desks, they know how to customize the clothes for each client

The whole manufacturing process is based on various data about human bodies and garment patterns, said Zhang.

At present, Red Collar has a database which contains anthropometric data for more than 2.2 million people. It's estimated that the database can meet 99 percent of customers' personalized demands.

The company has also designed a new type of bus in which 3D measuring equipment is installed. Customers can make reservations online and a bus will come to a customer's service.

From order to delivery, it takes only seven days to produce a man's suit at an inexpensive price.

Today, Red Collar has more than 3,000 employees and daily capacity is nearing 3,000 tailored garments. The company says customized production will be doubled in the near future.

Contact the writers at xiechuanjiao@chinadaily.com.cn and huqing@chinadaily.com.cn